News

The reaction to the pandemic and the resilience of the manufacturing sector are the primary motivation that led the Veneto Region to allocate extraordinary funding under the POR-programmeFESR 2014-2020 for Support to collaborative R&D activities for the development of new sustainable technologies, new products and services.

The project is supported by the SINFONET network, an innovative regional network on Foundry and Metalworking, in collaboration with M3NET, an innovative regional network on Precision Mechanics, Micro-Technologies and Additive Manufacturing. The project proposal was born from a wide and in-depth comparison with the Venetian system of companies and research, which allowed to identify, as a strategic line to guide the development of the Venetian socio-economic system in a post-emergency perspective, the "agile" conversion of production systems through the application of advanced solutions for product innovation.

The project has a declared manufacturing vocation, thus fully fitting into the "Smart Manufacturing" specialization. The proposing group intends to develop interdisciplinary methodologies and approaches, based on the ability of rapid and flexible conversion of processes and production lines, aimed at increasing competitiveness and product innovation. It is therefore an "industrial reaction" to the emergency COVID-19, built on flexibility, conversion and resilience, the results of which however have repercussions that exceed the time limits of the emergency, to place itself in a wider field of business competitiveness following the dictates of the new paradigm Industry 4.0.

In setting up AGILE, the partnership took account of

1) the continuous (as a result of COVID-19, but not only) mobility of manufacturing, industrial and market scenarios, which sometimes require, in a short or very short time, to vary the most green production models: to be competitive you need to be able to innovate quickly the product and adapt the production system accordingly

2) the need, in support of the drive for product innovation, processes (additive and conventional manufacturing, processing and transformation) and eco-systems (companies, districts, networks) that support in a structural way the rapid and agile reconfiguration of production lines: to effectively react to emergency situations, of any type, you need a structured, integrated, easily reconfigurable system

3) that an innovative product is only successful if it guarantees reliability and high performance, which must be measured and guaranteed: to ensure the quality of an agile production system, Innovative remote monitoring methodologies are needed with the support of AI and certification systems.

4) that the 'AGILE' reconfiguration of production processes and lines must nevertheless maintain a high level of competitiveness with equal quality/functional aspects and safety at work, also with the objective of increasing the manufacturing independence towards countries with socio-economic conditions different from those in Italy

The AGILE Project, halfway through this seminar, introduces these three aspects within specific (and well representative of regional manufacturing) types of production lines:

- foundry of aluminium alloys (1 mould-making company, with its own foundry) of magnesium alloys (1 mould maker integrated with a foundry) and cast iron (1 foundry),

- rolling and profiling of aluminium alloys (1 sheet metal producer and 1 company producing sheet metal forming systems),

- construction of welded components, in different materials (presence of 1 company producing welding systems and 1 company producing welded constructions).

The final project objectives are outlined with the degree of innovation on the different areas of activity:

1) Virtualization of the project phase: implementation in manufacturing companies partners of the project of integrated innovative solutions and systems for the management and optimization of the design chain (integrated process-product development); the integration and the personalization of the systems, regarding the peculiarities of the productive cycles, will be the main element of innovation

2) Development and industrialisation of advanced and rapid production technologies: the availability of components/products manufactured with highly innovative systems (additive manufacturing, hybrid processing systems, etc. ) will make it possible to appreciate new technologies and integrate them progressively into the production cycle: this is the most significant element of innovation

3) Rapid conversion and optimization of production lines: the development of experimental campaigns, customized to the 7 identified production lines, will demonstrate the feasibility of the various solutions proposed for the flexible management of product and batch variations; the innovation is certainly "system"typically consisting of the implementation of highly integrated and specialized solutions with respect to the peculiarities of the processes, with the progressive and personalized introduction of the concepts of kpis, OEE and with their finalization to the flexibility of the entire company production system

4) Intelligent quality management: monitoring and production control systems will be designed and implemented, with the possibility, through predictive quality models, to act in the management of process conditions; the traceability of products will be increased, to achieve their digital certification; these are innovative approaches developed so far in a "localized" and not systematic: their integrated introduction in various production contexts is the elementkey to innovative action.

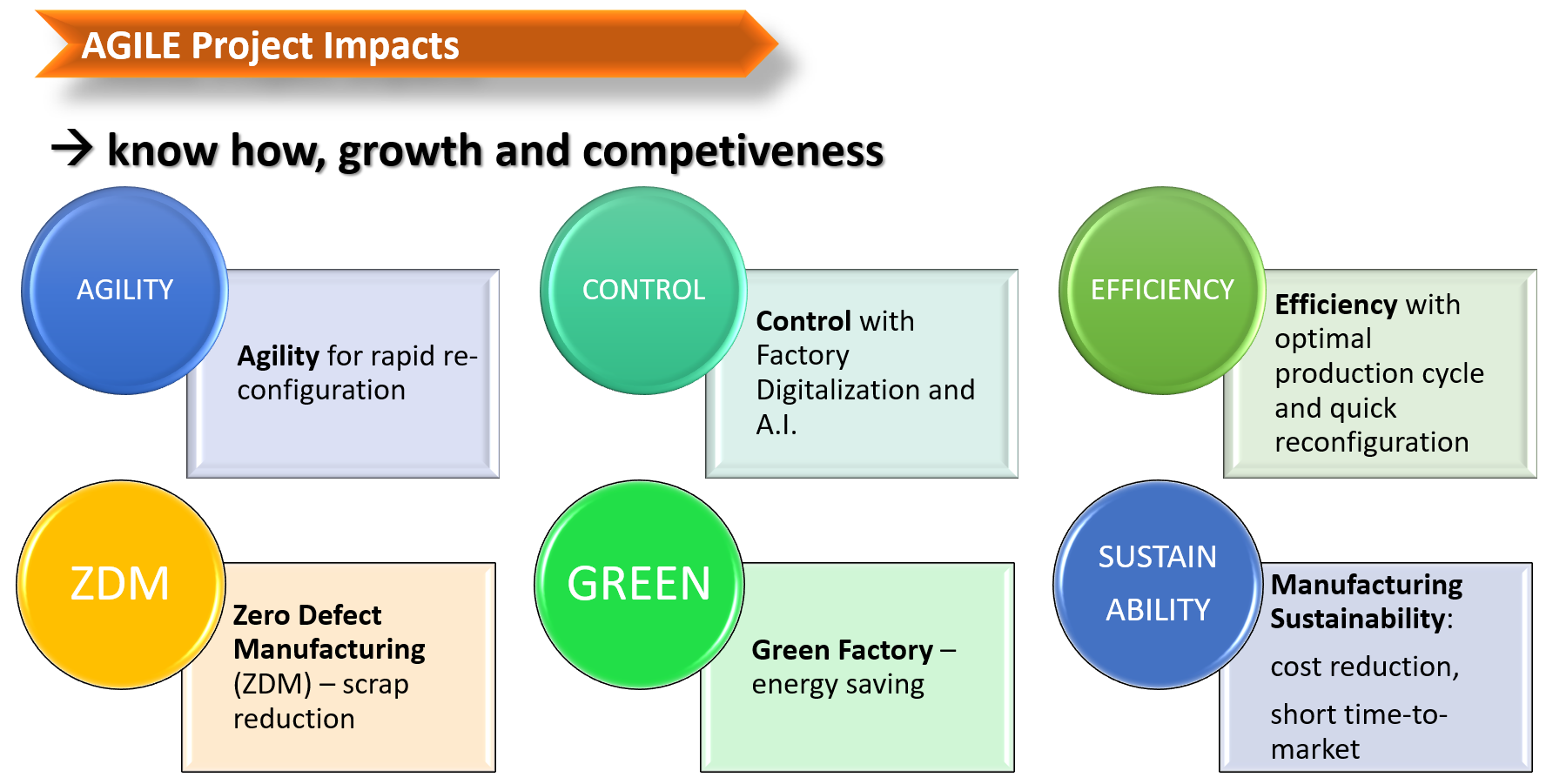

The impacts are attributable to all the elements characterizing Smart Manufacturing as shown in the following image:

Thanks again to the Veneto Region, the University of Padua, which has allowed the meeting to take place within the new university complex of Vicenza, allowing a large number of students to participate and to relate with new companies. Thanks also to all the partners of the Network: Fondazione Centro Produttività Veneto, ADI TOOLS s.r.l., Albertini Cesare S.p.A. a socio unico, Alfin Edimet S.p.A., AMS s.r.l, Antonio Carraro S.p.A., Buson S.r.l., Cestaro fonderie S.p.A., CNR - ICMATE, Confindustria Veneto SIAV s.p.A, DTG, University of Padua, ECOR Research s.p.A, Electronics GmbH, ELKEM S.r.l., Enginsoft S.p.A., FAB sas, FACES S.p.A., FIM Research s.p.A, FISEP S.r.l., ELKEM S.p.A., Fonderia Corrà S.p.A., Fonderia Pasubio S.r.l., Fonderia Volaro S.rcast.l., Fonderia Zardo S.p.A., Fonderie Anselmi S.r.l., Fonderie di Montorso S,p,A,, Fonderie Soliman S.p.A., Fratelli Comunelli S.p.A., GOM Italia S.r.l., Grimeca S.r.l., GSA S.p.A., Il Sentiero International Campus S.r.l., ITALKER S.r.l., Lino Manfrotto + Co Spa , M S.p.A., Marchetto F.srl. METEF S.r.l., Microsert sas, Modelleria Pozzan S.r.l., NETEDGE S.r.l., Raffmetal S.p.A., Rds Moulding Technology S.p.A., RTM Breda s.r.l., SAEN S.r.l., SAFASS S.p.A., SATEF HUTD ALBERTTENEUS S.p.A., SAV A S.p.A., Schneider electric S.p.A., S.P.A., ROLLING FUSINA S.R.L., Speedline - Ronal Group, Sviluppo Foprmazione Scarl, Tecnolabor S.r.l., TMB S.p.A., TMD DEMOTECH, Trevisan S.r.l., Unilab laboratori industriali S.r.l., VDP fonderia S.p.A., Zanardi fonderie S.p.A., Zintek, Zoppelletto S.p.A.

The SINFONET Network hopes to see more of you at the upcoming AGILE Project update meetings.

.jpg)