News

News about activities of the Network

- Final meeting on the AGILE Project:

The final event for the AGILE Project (AGILE Manufacturing for Competitiveness and Product Innovation), a project coordinated by the SPRING Consortium that manages the SINFONET Regional Innovative Network, took place on 07 September 2022. The project proposal was born from a wide and in-depth comparison with the Venetian system of companies and research supporting the development of the Venetian socio-economic system in post-emergency with the ability to "agile" conversion production systems through the application of advanced solutions for product innovation.

The two innovative Networks SINFONET and M3NET have built a partnership able to represent the production chains of foundry, deformation and junction, in symbiosis with the DTG and DII departments of the University of Padua and with the ICMATE Institute of CNR.

The realization was possible thanks to the POR (Objective - "Increase of the activity of innovation of the enterprises") financing. The duration of the Project was 24 months, from 10/09/2020 to 09/09/2022 and thanks to the final meeting held on 07/09/2022 it was possible to summarize the objectives achieved and the results obtained by the various Partners.

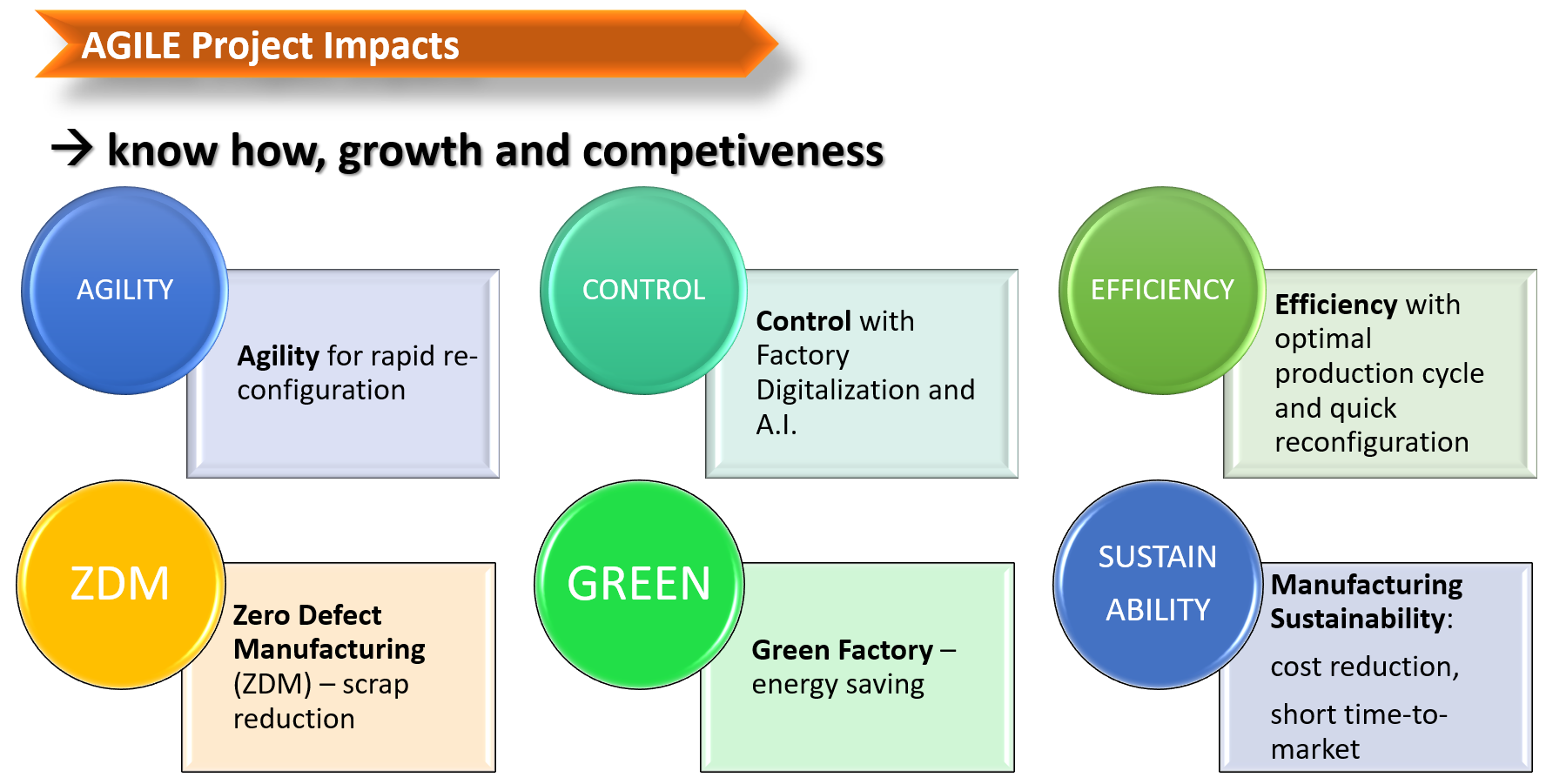

The usual "Zero Defects" challenge is joined by the concept of Agility for a quick reconfiguration of the production line while maintaining high real-time control of the process parameters to identify the most significant deviations. The Sustainability of the single phases of the process of transformation of the metallic members implies the optimization of the productive cycle, the reduction of scraps and costs, and the minimization of the time-to-market. All this translates into production efficiency and better management of energy and human resources.

The AGILE Project intercepts, with various modalities and intensity, the following development trajectories relevant to the Smart Manufacturing field:

2) "New plants, innovative components, energy saving"

3) "Tools and models for the integrated, innovative and multi-scale design of innovative equipment for manufacturing processes"

4) "Innovative micromechanics"

5) "Development/production of innovative materials"

6) "Innovative solutions, equipment, safety and protection"

7) "Maintenance, Quality, Logistics, Decision Support"

8) "Intelligent Machines, Automation and Robotics"

Ultimately, the AGILE project is in full coherence and continuity with the enabling technologies, drivers and trajectories identified in the RIS3 of the Veneto Region, and is fully integrated into the system of solutions at Community level for an effective response to the VOC-19 emergency.

1) Development and industrialization of advanced and rapid production technologies

2) Fast conversion and optimization of production lines

3) Rapid reconfiguration and optimization of production lines

4) Intelligent quality management and control/testing methods

- Il 39th AIM National Conference in Padova:

The AIM National Conference is the reference initiative for company technicians, researchers and academics working in the metallurgical field, in the development of engineering components along the entire supply chain or in the innovation of manufacturing technologies. In the three days of the Conference, the centrality of metallurgy with respect to the issues of ecological transition, sustainable mobility, circular economy and the increasingly high performance required of any mechanical component will be reaffirmed and documented. Materials, products, processes and technologies, innovative solutions for the various production sectors will be analyzed.

They will also be stimulated and proposed insights on the collaborations between the University and the world of industry in perfect accordance with the principles and objectives of the SINFONET network.

The first day, on the 21/09/2022, the opening ceremony was held, accompanied by an analysis of the steel cycles. Then we moved on to an analysis of processes and materials, always remaining on the subject of steel making. Meanwhile, conferences on manufacturing, raw materials, structures and ferrous alloys were held in other classrooms. In another classroom, collaborative projects were discussed, including AGILE.

This year the SINFONET network had the honour of being a sponsor of the AIM Conference and some partners of the AGILE project presented the final results of the project in the afternoon session on the 21st of September.

The SINFONET Network thanks all members for their reading and participation.

For any need, you can contact us at privacy@consorziospring.org.

.jpg)

.jpg)